D Soar

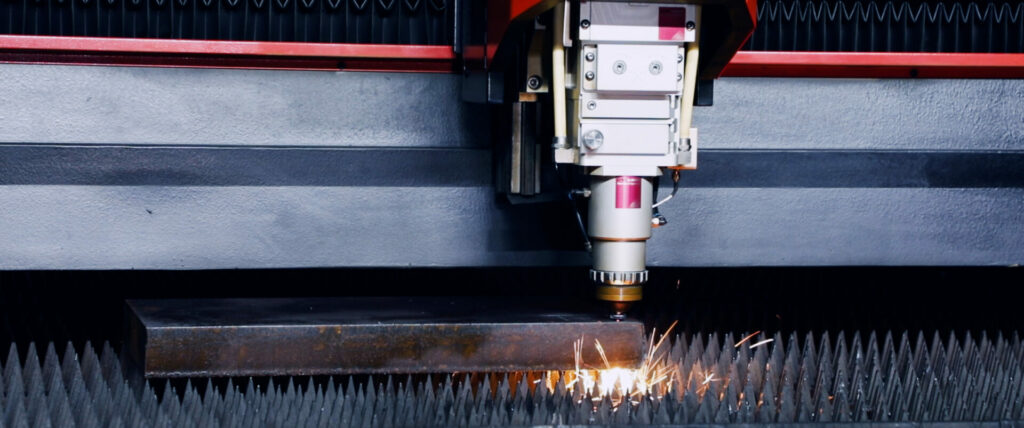

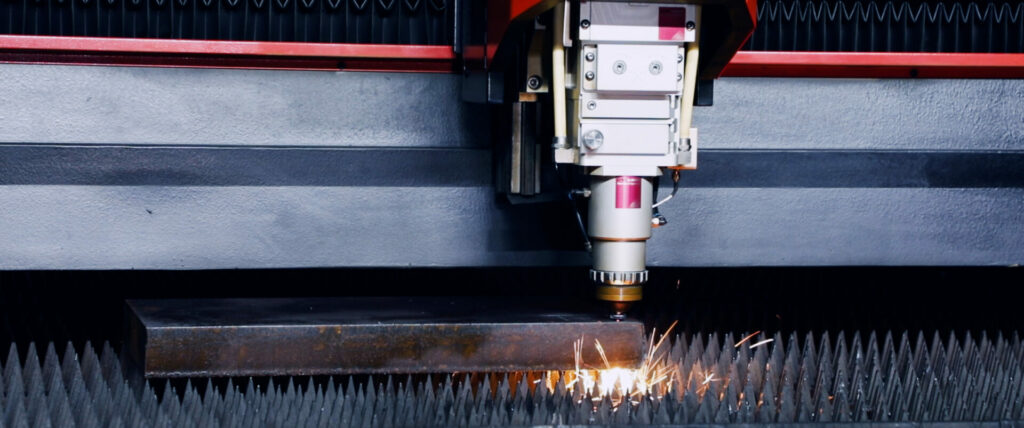

D-SOAR Series Fiber Laser Cutting Machine

Increased productivity

Versatile Applications

It handles several different materials, such as steel, aluminum, copper and brass. The wide material capacity makes the machine useful in many types of industrial production.

High Performance

With a power output of up to 30 kW, fast cutting with high quality and precision is achieved.

Video clip about D-SOAR fiber laser cutting machine

Technical data for the D-SOAR series:

| Effect | Fiber 3000 | Fiber 4000 | Fiber 6000 | Fiber 10000 |

|---|---|---|---|---|

| Adjustment range (W) | 300 – 3000 | 300 – 4000 | 600 – 6000 | 1000 – 10000 |

| Wave-length | 1080 nm | 1080 nm | 1080 nm | 1080 nm |

| Steel (maximum sheet thickness) | 16 mm | 18 mm | 20 mm | 25 mm |

| Stainless steel (maximum sheet thickness) | 12 mm | 14 mm | 16 mm | 22 mm |

| Aluminum (maximum sheet thickness) | 8 mm | 8 mm | 10 mm | 14 mm |

| Brass (maximum sheet thickness) | 4 mm | 6 mm | 8 mm | 10 mm |

| Copper (maximum sheet thickness) | 6 mm | 8 mm | 15 mm | 20 mm |

| Total system power consumption (with vacuum cleaner and cooling) | 46 kW | 50 kW | 56 kW | 80 kW |

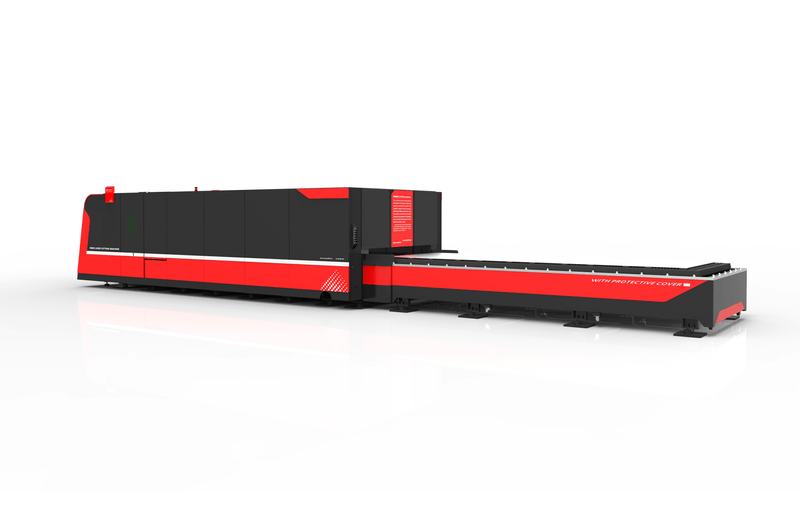

| Parameter | D-SOAR 1530 | D-SOAR 2040 | D-SOAR 2060 | D-SOAR 2560 | D-SOAR 2580 |

|---|---|---|---|---|---|

| Längd [P] | 8550 mm | 10 910 mm | 15 580 mm | 15 580 mm | 20 100 mm |

| Bredd [L] | 3050 mm | 3500 mm | 3500 mm | 4100 mm | 4100 mm |

| Höjd [K] | 2600 mm | 2600 mm | 2600 mm | 2500 mm | 2500 mm |

| Normal plåtstorlek [X] | 1500 mm | 2000 mm | 2000 mm | 2500 mm | 2500 mm |

| Normal plåtstorlek [Y] | 3000 mm | 4000 mm | 6000 mm | 6000 mm | 8000 mm |

| Skärområde [X] | 1550 mm | 2050 mm | 2050 mm | 2550 mm | 2550 mm |

| Skärområde [Y] | 3050 mm | 4100 mm | 6100 mm | 6100 mm | 8100 mm |

| Skärområde [Z] | 270 mm | 270 mm | 270 mm | 270 mm | 270 mm |

| Max positioneringshastighet, en axel X/Y | 90 m/min | 90 m/min | 90 m/min | 90 m/min | 90 m/min |

| Max positioneringshastighet samtidigt | 120 m/min | 120 m/min | 120 m/min | 120 m/min | 120 m/min |

| Repeternoggrannhet för en axel R | ±0,02 mm | ±0,02 mm | ±0,02 mm | ±0,02 mm | ±0,02 mm |

| Medelfel i positionering för en axel M | ±0,5 mm | ±0,5 mm | ±0,5 mm | ±0,5 mm | ±0,5 mm |

| Noggrannhet för kantigenkänning | ±0,5 mm | ±0,5 mm | ±0,5 mm | ±0,5 mm | ±0,5 mm |

| Maxvikt för arbetsstycke | 1000 kg | 1900 kg | 2800 kg | 3500 kg | 4700 kg |

| Maskinens vikt (utan kylare och dammutsug) | 8100 kg | 11 800 kg | 16 600 kg | 17 600 kg | 23 700 kg |

| Bordets växlingstid (2 nivåer) | 17 s | 20 s | 25 s | 25 s | 32 s |

| Bordets växlingstid (1 nivå) | 50 s | 55 s | 60 s | 60 s | 85 s |

| Effect | Fiber 12000 | Fiber 15000 | Fiber 20000 | Fiber 30000 |

|---|---|---|---|---|

| Adjustment range (W) | 1200 – 12000 | 1500 – 15000 | 2000 – 20000 | 3000 – 30000 |

| Wave-length | 1080 nm | 1080 nm | 1060 – 1080 nm | 1060 – 1080 nm |

| Steel (maximum sheet thickness) | 30 mm | 40 mm | 60 mm | 80 mm |

| Stainless steel (maximum sheet thickness) | 30 mm | 40 mm | 50 mm | 80 mm |

| Aluminum (maximum sheet thickness) | 25 mm | 30 mm | 40 mm | 50 mm |

| Brass (maximum sheet thickness) | 10 mm | 10 mm | 10 mm | 10 mm |

| Copper (maximum sheet thickness) | 25 mm | 30 mm | 30 mm | 40 mm |

| Total system power consumption (with vacuum cleaner and cooling) | 100 kW | 115 kW | ≤110 kW | ≤140 kW |

Versatile metal processing

D SOAR series fiber laser is suitable for processing various metals and thicknesses. The machine guarantees high cutting quality, accuracy, speed and efficiency. Low operating costs and high productivity ensure a quick return on investment.

Advanced control and security features

The D-SOAR series machines are equipped with a closed protective structure that meets CE safety standards. The high-quality components guarantee excellent efficiency, dynamic characteristics and precision cutting. The customized control system with a powerful test program simplifies both the use and programming of the machine.

In addition, active protection systems such as collision protection, intelligent breakthrough functions and warning systems ensure safe and reliable operation.

Flexible and upgradable

The D-SOAR series has a user-friendly interface that speeds up efficient implementation. The system is fully compatible with MES or ERP systems and can be connected to an IoT cloud platform, allowing customers to visualize and manage their orders, production processes, delivery schedules and much more. The system is easy to expand and upgrade as needed.

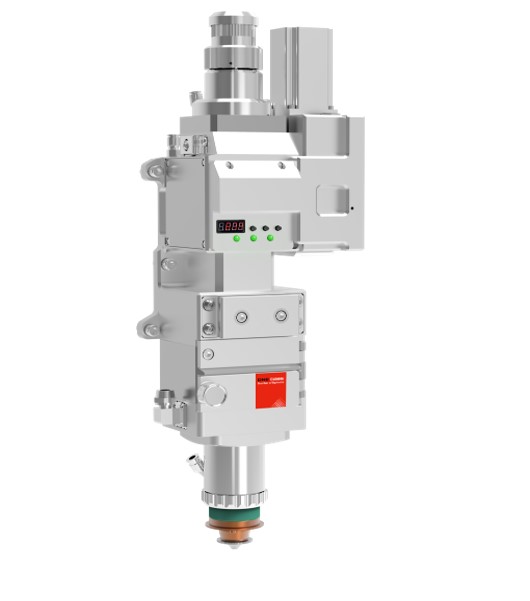

By-Power cutting head with smart features

- Intelligent sensor and control system

- Automatic cleaning system for the cutting head

- Real-time monitoring of the cutting head via mobile phone

- Automatic tracking and collision avoidance

- Autofocus system with optimized heat management and tight design

- Unik kylsystemslösning (luftkyld + vattenkyld munstyckskylning)

Robust frame construction

The frame design utilizes engineering mechanics and an embedded V-groove welding with reinforcements and double external walls, which improves the stability of the structure. The stiffening plates use an embedded welding method to ensure strong joints in the support brackets, ensuring high precision and stability for long-term use. The entire machine frame undergoes stress relief annealing before machining.

Die-cast aluminum portal

The die-cast aluminum gantry is lightweight, which reduces inertia and improves vibration damping. The movement is carried out with rack and pinion drive on both sides, with two servo motors.

The lightweight yet robust construction allows for higher acceleration without compromising precision.