D Trans

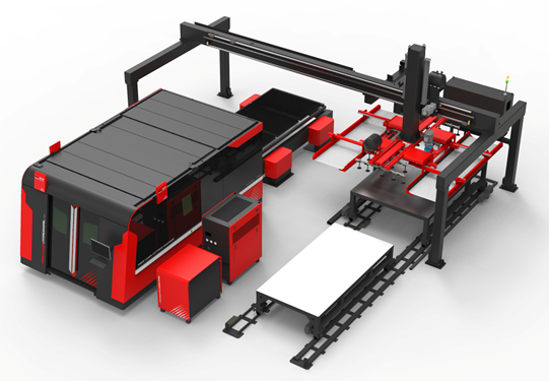

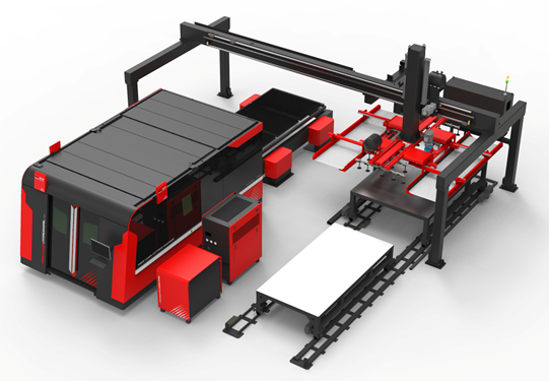

D-Trans Automated Loading and Unloading System

D-Trans is an automatic loading and unloading system for laser cutting machines. Its standard configuration includes a frame with guide rail, an integrated control cabinet, and a combined suction cup and double fork unit.

The suction cup loading positions are adjustable to suit different standard sheet sizes. Thanks to the double fork structure, the fork unit can safely lift and transport cut sheets from both sides to the unloading table.

The system is also equipped with necessary safety features, such as protective fencing and light curtains, to ensure safe and efficient operation.

Modular and flexible

Improved safety and precision

The system is equipped with removable suction cups, an air blowing system and a double layer detector that prevents loading errors caused by double plates.

High efficiency in material handling

D-Trans ensures smooth and fast material handling, which increases the machine's productivity.

Video clip about D-Trans

Benefits

• Easy to expand and can be connected to different storage systems

• High flexibility for specific requirements or limited space

• Fully automated loading and unloading function with high productivity for 24/7 operation

• Meets Bystronic standards

• Stable and robust design

• Customized solution with standard components

D-Trans functional description

A loading gripper lifts a single sheet from the raw material table. The sheet is separated and any double sheets are detected with dedicated equipment before the raw material is placed on the change table. The sheet is then moved into the laser machine for cutting. The processed sheet is removed from the change table by a fork unit and transferred to an unloading table.

DNE Smart Factory Solutions

DNE offers automation solutions that integrate different parts of the production flow into a coherent system. This includes traditional automation complemented by technology for “intelligent” factory automation. The solutions are designed to streamline production steps and provide increased value for investments made.

Smart Factory

• Automatic material supply and routing

• Unmanned automatic production

• Easy management of the production process

• Automated order management and scheduling